[ad_1]

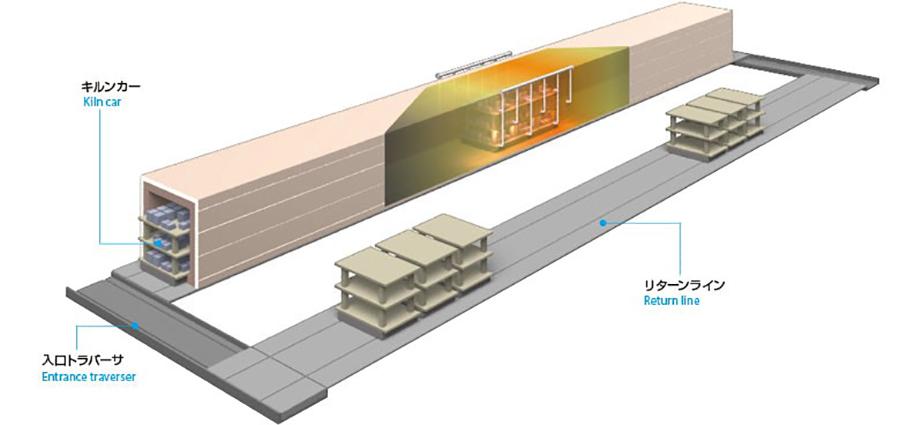

Image of Tunnel Kiln for ceramic firing (Source: NGK Insulators, Ltd.)

Tokyo, November 8, 2023 – Mitsubishi Heavy Industries, Ltd. (MHI) completed delivery of a compact CO2 capture system CO2MPACT™ in September, which received order from NGK INSULATORS, LTD. (NGK) last year. The system has been installed adjacent to a tunnel kiln used for ceramic firing at NGK’s plant in Nagoya, Aichi Prefecture and recently began commercial operation. This is the second MHI CO2MPACT™ system to be put into commercial operation.

The CO2MPACT™ delivered to NGK has a 0.3 metric tons per day (tpd) capacity. The highly versatile standard design has been modularized to support a broader range of applications in various industrial fields, allowing for ease of transport and installation, and a shorter time to delivery. MHI received an order of CO2MAPT from NGK which aims demonstration test for the utilization of captured CO2 This is the first attempt in the world to apply CO2 capture technology in the ceramic manufacturing field.

CO2MPACT™ received the “Awards for Excellence” at the 2022 Nikkei Excellent Products and Services Awards(Note1) in January 2023, and the “Award By The Japan Electrical Manufacturers’ Association” at the 53rd Machine Design Award IDEA(Note2) in July. The concept has been highly praised by customers and organizations in Japan and overseas. Going forward, MHI will continue to enhance its presence, aiming for more widespread adoption of CO2MPACT™ among stakeholders pursuing carbon neutrality in various industrial fields, and expanding business opportunities.

NGK is pursuing initiatives to reduce CO2 emissions from production facilities across its corporate group. NGK has adopted “NGK Group Environmental Vision” with a target of net zero CO2 emissions by 2050 and is advancing efforts to achieve net zero ahead of schedule through its “the Net Zero CO2 Emissions Project”. The introduction of CO2MPACT™ is an extremely significant and groundbreaking measure for NGK in terms of accelerating action to reach carbon neutrality, which is part of this project, and for MHI in terms of the standpoint of contributing to the decarbonization needs in new industrial fields.

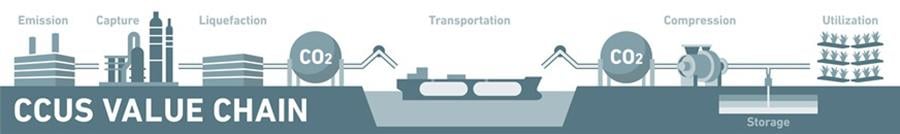

MHI Group has made a declaration to achieve carbon neutrality by 2040 and is pursuing strategic measures for decarbonization for both the energy supply and demand sides. One of the core elements of the “Energy Transition,” a decarbonization strategy for the supply side, is establishing a CO2 solutions ecosystem that links diverse carbon emission sources with solutions for storage and utilization. Going forward, MHI Group will continue to solidly pursue its carbon dioxide capture, utilization and storage (CCUS) business built on its unique CO2 capture technology, and as a solutions provider, contribute to the reduction of greenhouse gas emissions on a global scale, and further develop solutions that help protect the environment.

- 1 For details of CO2MPACT™ receiving “Awards for Excellence” at the 2022 Nikkei Excellent Products and Services Awards, see the following press release:

https://www.mhi.com/news/230201.html - 2For details of CO2MPACT™ receiving “Award By The Japan Electrical Manufacturers’ Association” at the 53rd Machine Design Award IDEA, see the following press release:

https://www.mhi.com/news/230810.html

CO2MPACT™ Compact CO2 Capture System

About MHI Group’s CO2 capture technologies

MHI Group has been developing the KM CDR Process™ (Kansai Mitsubishi Carbon Dioxide Recovery Process) and the Advanced KM CDR Process™ in collaboration with The Kansai Electric Power Co., Inc. since 1990. As of November 2023, the Company has delivered 16 plants utilizing the KM CDR Process™, with two additional plants currently under construction. The Advanced KM CDR Process™ uses the KS-21™ solvent, which incorporates technological improvements over the amine-based KS-1™ solvent used in all 16 of the commercial CO2 capture plants MHI has delivered to date. KS-21™ offers superior regeneration efficiency and lower deterioration than the KS-1™, and has been shown to provide excellent energy-saving performance, reduced operating costs, and low amine emissions.

For further information on MHI Group’s CO2 capture plants:

[ad_2]

Source link