[ad_1]

Top Shops 2023 business strategies honoree Manda Machine is a family business. Operations manager Todd (left) and general manager Andy (right) Ellard are the third-generation owners, and foreman Stephen Waldrop (center) is Todd’s son-in-law. Photos courtesy of Manda Machine.

Manda Machine is a Dallas, Texas-based machine shop that was founded in 1950 and is currently led by third-generation owners Andy and Todd Ellard. (Their oldest brother, Richard, retired a few years ago.)

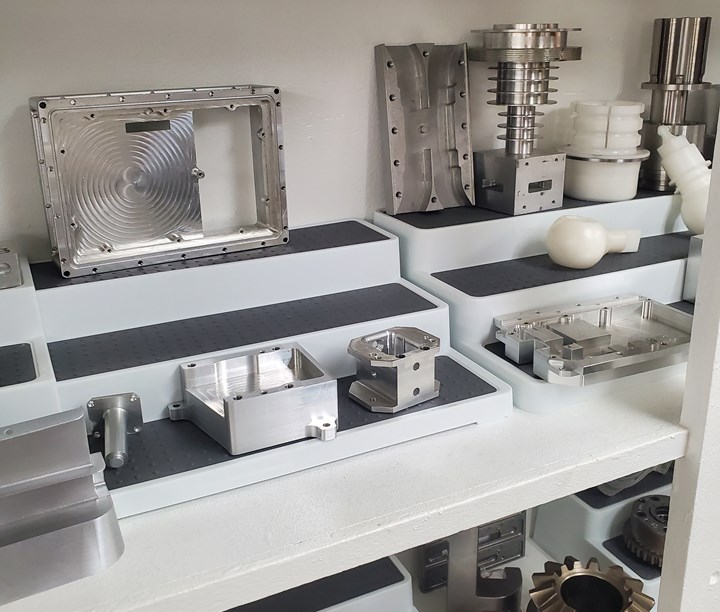

The company’s 17 employees work out of an 8,500-square-foot building with five manual machines, nine CNC milling machines (two five-axis, two four-plus-one and five three-axis machines) and three CNC lathes (two of which have live tooling), specializing in short runs of complex work for aerospace and defense, oil and gas, medical, packaging, power generation, and general industry.

But this wasn’t always the case. Manda Machine used to take on a much wider variety of work, and only within the last 10 years has the company defined a niche for itself.

The decision has had wide-reaching impacts throughout the company, to the extent that when asked on the 2023 Top Shops survey about the technology, strategy or initiative that has been most influential to the success of your shop in recent years, co-owner and general manager Andy Ellard responded with, “Choosing the right customers and work.” This response caught the attention of Modern Machine Shop’s editors and led to Manda Machine being chosen as the 2023 Top Shops Honoree for Business Strategies.

Manda Machine used to quote all different types of work, but in recent years, it has narrowed its focus. This decision has had positive impacts in both the front office and on the shop floor.

‘If We’re Not Going to Do It, Somebody Else Is’

Until the mid-2010s, Manda Machine didn’t have a specific strategy for the types of work it took, quoting almost everything it came across. “Back then, it was, they’re looking for somebody. If we’re not going to do it, somebody else is going to do it,” says co-owner and operations manager Todd Ellard.

With this strategy, Andy says the business was working well, but not as well as it could have been because the company was putting resources into jobs that weren’t as profitable. He describes how the shop once bought a Swiss-type machine for a new job. “I was so thankful when the customer said, ‘Y’all just seem to can’t make these parts.’ And I’m like, ‘You’re right. Thank you! Take the contract away from us,’” he says. “We sold the machine and replaced it with a three-axis milling machine and never looked back.”

The catalyst for making a strategic change came during an economic downturn around 2016 and 2017. Andy and Todd have led the business through several other economic ups and downs, but they wanted to find a way to “smooth the roller coaster ride.”

Todd says that after years of experience, he can quickly tell which jobs to quote. Now, the shop takes mostly complex, low-volume jobs on its milling machines and short runs of intricate parts on its live tooling lathes.

‘Don’t Try to Do Everything for Everybody’

Leadership didn’t undertake a formal process when determining Manda Machine’s niche. Andy says the decision-making process was largely based on the experience they had gained over the years. “You figure out what you can do and not do, and you don’t try to do everything for everybody. Because we can’t. We’re not big enough,” he says.

Where Manda Machine excels, they realized, is small, complex work. “We got rid of the commodity parts,” Todd says. Even on the lathes, where volumes are higher, the shop still seeks out jobs that are more intricate and better suited to its live-tooling lathes.

“We’re not going to chase pennies,” he adds. “We increased our labor rate, charged more. We cut customers, got new customers and serviced the customers that were good. And our business actually started increasing.” After making these changes, the company was growing 15-20% per year until the COVID-19 pandemic, and business is now back above 2019 levels.

As Todd mentioned, these changes necessitated letting go of some customers. The two went through the business’s customer list and evaluated each one.

Obviously, the most important consideration was how much money the business was making on a job. The next consideration, according to Andy and Todd, was how much time and attention they require. Balancing these two factors gave them a good idea of which customers were worth retaining.

Ultimately, Andy says the shop let go of five or six of its 30 customers. It also means turning down jobs it has taken previously, or charging more for them. “Just because we ran it before doesn’t mean we’re going to run it again,” he says. “And I think that’s okay. I really do.”

Once Manda Machine made this decision, it started growing at a rate of 15-20% per year. The shop was also able to better optimize and streamline its processes.

‘The Warm Fuzzies’

The days of quoting every job are over. Again, deciding what to quote and not quote is largely based on experience. “When I sit down to quote stuff, if I look at the prints and I don’t get warm fuzzies right off the bat, I don’t quote it and I don’t feel bad,” Todd says.

So what types of jobs give Todd “the warm fuzzies?”

- Low Quantity. The shop looks for low-volume jobs because it isn’t set up for high-production work, especially on its milling machines.

- High Quality. “We like to run fairly tight tolerance stuff,” Todd explains.

- Value-Added Work. This includes complex assemblies that involve sending parts out for plating, heat treating, grinding or EDM. “A lot of companies don’t want to do that kind of stuff,” he notes. “We found out over the last few years we’re good at it.”

- Certain Materials. The shop’s core competency on its mills is aluminums, stainless steels and titaniums. For milling work, Todd says that the shop isn’t great with carbon steels. “We are on the lathe,” he says. “But on the mill, we’re just not.”

‘Less Time Chasing After the Problems’

Once the company had identified its strengths, improving processes became easier. “You spend less time chasing after the problems,” Andy says. “You get to spend more time looking at those things that really affect your business and you can make adjustments to them.”

By testing new tools and optimizing programs, machinists have reduced cycle times for some parts from 45 minutes to less than 20. The company has also optimized its assembly area based on the 5S principles of sort, set in order, shine, standardize and sustain to maximize efficiency.

The shopfloor is also much more streamlined now, says foreman Stephen Waldrop. He notes that when the shop was taking on a wide variety of work from many different customers, a hot job would throw a wrench into the system and mess up the flow of other jobs. Standardizing the types of work and customer base makes this less likely. “It’s allowing us to be able to really smooth out a lot of stuff as far as the day-to-day operations in the shop,” he explains.

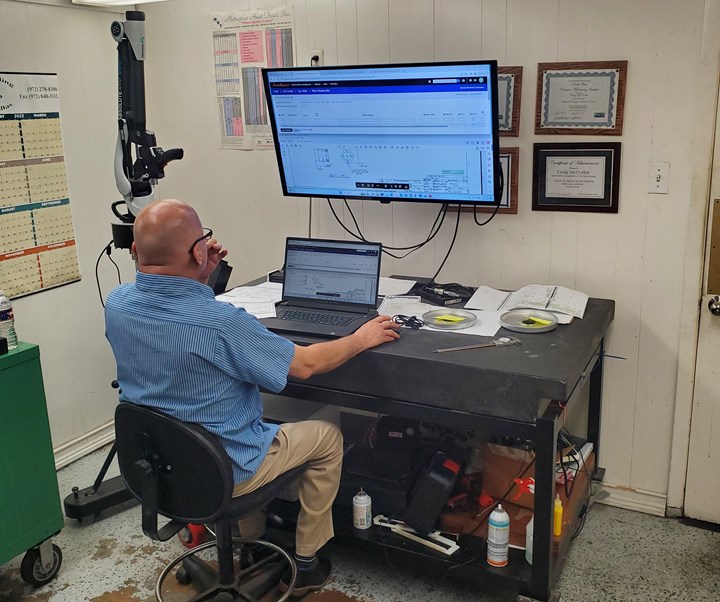

Defining a niche has also enabled Manda Machine to refine the way it invests in new technology. Most recently, the shop has added a laser scanner and dedicated employee for quality, along with ProShop ERP and IT infrastructure in preparation for AS9100 and cybersecurity maturity model certification (CMMC).

‘Once We Make a Decision, We’re Done’

Another benefit is that when Manda Machine does invest in a new machine or capability, it can fully commit to it. Purchasing new technology is a risk, and if manufacturers aren’t sure that an investment is going to pay off, they might be tempted to go with a cheaper version, or not invest in additional features (whether that’s high-pressure coolant, chip conveyors or measuring capabilities), training and high-quality tooling.

Keeping the business strategy in mind helps mitigate risks when making investments, Andy says. “What if we invest in this stuff, but then the customer goes away? Now we’ve got all this stuff. Can we use it for something else?” he says. “We really go through that in our heads.” With this in mind, the business makes purchases with confidence. “Once we make a decision, we’re done,” Todd says. “I’ve never looked back. I don’t have any buyer’s remorse.”

Waldrop cites Manda Machine’s recent investments in its quality department as an example, which include a seven-axis Hexagon laser scanner and a full-time, dedicated employee to manage quality. It’s also working toward AS9100 certification as well as cybersecurity maturity model certification (CMMC) to grow its aerospace and defense business. This has included a new ERP (ProShop), as well as hiring a firm to manage IT and implementing cybersecurity measures.

‘If We Can’t Make Money…It Ain’t Worth Doing’

Determining a shop’s niche isn’t a one-time decision — it’s an ongoing process, according to Andy and Todd. The two are continually discussing which jobs to quote and which customers to work with or let go. And even with a strategy, execution isn’t always perfect. “If we can’t make money doing it, it ain’t worth doing,” Andy says. “Like everybody, we’ve done that before. We’ve done it many times, and I’m sure we’ll do it again in the future. But we try to limit that.”

Landscape Photo Credit: Manda Machine

RELATED CONTENT

-

Behind Schedule Preparing for CMMC? You Are Not Alone.

The Department of Defense appears to be on track to begin a phased rollout of its Cybersecurity Maturity Model Certification assessment program by early 2025. What does that mean for defense contract manufacturers and suppliers?

-

Top Shops: Do You Have What It Takes?

Modern Machine Shop’s Top Shops Program is more than just an honor—it’s a pathway to excellence. The annual benchmarking program is an opportunity to guide your shop’s improvement efforts and gage where you rank among industry-leading machining businesses. This interactive story helps you decide: How does your business stack up?

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

[ad_2]

Source link