[ad_1]

As-deposited morphology and resistive switching forming process

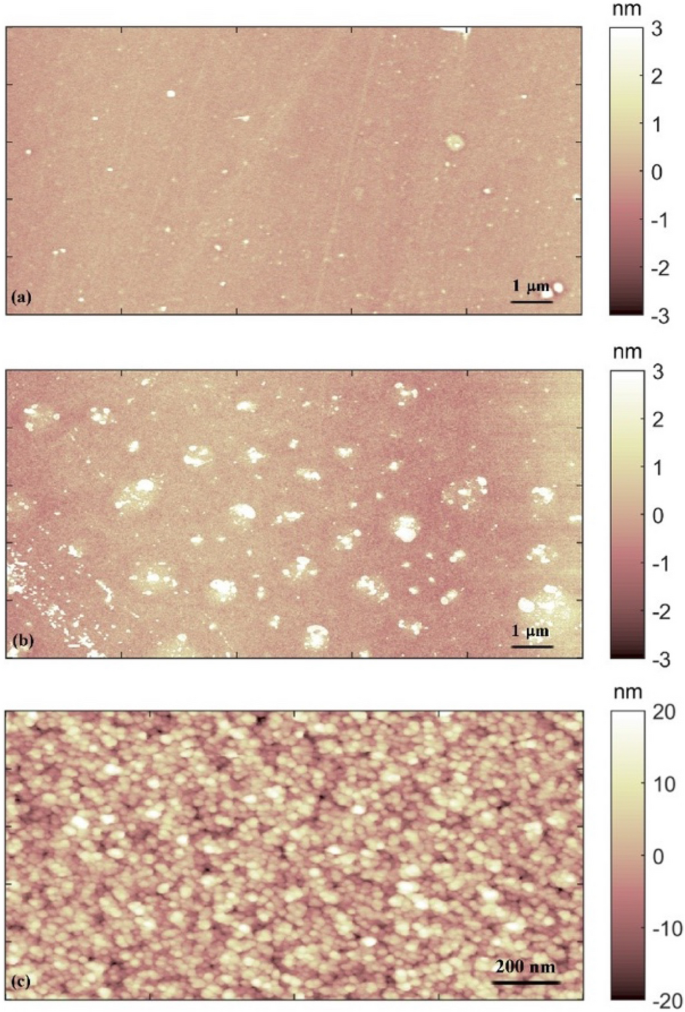

The morphology of the ns-Au thin films can be affected by the nanoscale features characterizing the interface of the substrates, i.e. oxidized silicon (SiOx) and glass. To test this hypothesis, we evaluated the root-mean-square roughness (Rq) of the substrates, calculated by AFM images as the ones reported in Fig. 3a,b; Rq results 0.34 ± 0.05 nm for SiOx and 0.88 ± 0.3 nm for glass. The morphology of the ns-Au film, a typical AFM image of the as-deposited cluster-assembled gold film is shown in Fig. 3c, appears as a granular and porous matrix composed by a huge number of few nanometres large clusters26,41, impinging on the substrate with kinetic energy low enough to prevent them from a post-deposition fragmentation upon the surface41. The roughness of the deposited ns-Au film, which increases with the thickness (t) of the film according to a power law (Rq ⁓ tβ)41, is 3.5 ± 0.5 nm. The as-deposited ns-Au films appear with the same granularity and result in same roughness values on both SiOx and glass substrates.

AFM images of the (a) SiOx substrate, (b) the glass and (c) the as-deposited ns-Au thin film on a glass substrate.

As-deposited gold thin films in the thickness range of 15–40 nm showed ohmic electrical behaviour, as for each explored thickness above the percolation threshold26.

The resistive switching forming procedure consisted in circulating high current densities up to 109–10 A/m2, for about 90 ± 11 s for ns-Au/SiOx and 30 ± 3 s for ns-Au/glass; this caused the modification of the film morphology, structure, and electrical behaviour26,42,43. By high current circulating through the film, we observed a first resistance decrease for granular network reorganization (with a reduction of up the 50% of the initial value), in contrast to the expected ordinary joule-effect related resistance increase observed in metals, followed by a gradual increase of the resistance (up to the double of the initial resistance value in about 1 s) with a final abrupt resistance increase of about 1–3 orders of magnitude27. At this point the cluster-assembled films started to exhibit a stable resistive switching activity and we observed non-linear electrical behaviour26,28,29. The described RS forming procedure resulted in different electrical and structural evolutions depending on the type of substrates, as reported here after. The ns-Au deposited on ultra flat SiOx and subjected to RS forming procedure remains ohmic even after circulating current densities up to 1010–11 A/m2.

Reorganization of the network structure

Mutually correlated interfacial phenomena, as electro-migration and joule heating, occurring at the interface with the ns-Au film can lead the metallic network to a reorganization of its structure and morphology42,43. In Table 1 the structural parameters extracted from XRD patterns are reported for the as deposited ns-Au sample, the switched ones on glass and on SiOx and for the ns-Au/SiOx ultra flat sample which manifested ohmic electrical behaviour even after the procedure to trigger the RS activity. It is important to note here that all the XRD measurements were done in ambient conditions and not in-situ during the electrical treatment. The error bars denote the uncertainty of the analysis done by the whole powder pattern fitting program MStruct on measured data.

The RS forming procedure causes an increase in the mean size of crystallites and a decrease in the number of stacking faults, comparable for the systems on both substrates. In the case of ns-Au/SiOx samples after the forming procedure the microstrain, i.e., the distribution of interplanar spacings, vanishes completely pointing to more ordered crystal structure compared to the system on glass substrate. Conversely the persistence of microstrains in the ns-Au/glass system suggests a still granular and rough morphology characterizing the network at the nanoscale. In fact, the surface is known to induce microstrain in the nanostructure and so smaller structures result in enhanced microstrain44,45,46.

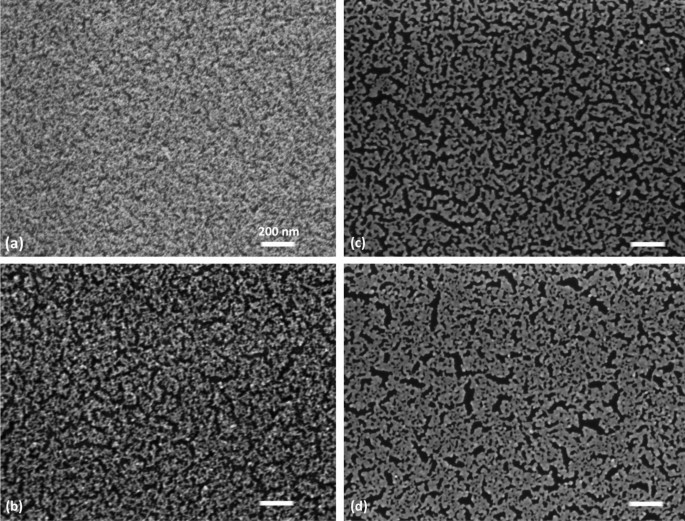

Figure 4a–d reports the SEM images of the as-deposited ns-Au sample (we reported the one deposited on glass, which is similar to the one deposited on SiOx), the two formed ones and the ns-Au unsuccessfully formed on ultra flat SiOx; the image of the formed ns-Au/glass sample confirms qualitatively the hypothesis evidenced by XRD measurements. The formed networks are characterized by a complex and highly interconnected network at the mesoscale, while the paths of gold on ns-Au/SiOx sample are more flattened and looks less granular at the nanoscale compared to the ns-Au/glass system.

(a) SEM images of the ns-Au as-deposited on the glass substrate, (b) on the same substrate after the forming process, (c) ns-Au/SiOx substrate after the forming process and (d) SEM images of the ns-Au deposited on the ultra flat SiOx substrate after unsuccessfully RS forming process, in particular after the application of 35 V.

In order to evaluate the differences in the gold networks formed on glass and on SiOx substrate at the mesoscale, we have performed an analysis of the SEM images by home-made MATLAB routines, described in Materials and Method section, to evaluate the connectivity of the complex structure, on more than five images for each sample. The morphologies of the two formed and switching networks have almost comparable surface coverage (54 ± 1% on SiOx and 61 ± 5% on glass), but they are composed by different density of holes (191 ± 17 #/µ\({\mathrm{m}}^{2}\) on SiOx and 236 ± 49 #/µ\({\mathrm{m}}^{2}\) on glass), of endpoints (142 ± 20 #/µ\({\mathrm{m}}^{2}\) on SiOx and 300 ± 84 #/µ\({\mathrm{m}}^{2}\) on glass) and of nodes (854 ± 71 #/µ\({\mathrm{m}}^{2}\) on SiOx and 1222 ± 171 #/µ\({\mathrm{m}}^{2}\) on glass). In general, the morphology at the mesoscale of ns-Au formed on SiOx is more compact and well connected, compared to the ns-Au/glass system which appears more fragile and further from the continuous layer. This nicely corresponds to the findings from XRD analysis, by which we observed in general more ordered crystal structure for the ns-Au system on SiOx substrate.

Interestingly, the network of the ns-Au/SiOx ultra flat at the mesoscale is more compact (Fig. 4d), since the density of endpoints (75 ± 10), nodes (395 ± 30) and holes (145 ± 35) decreases compared to the ns-Au morphology on glass and on SiOx. The coverage of ns-Au switched on SiOx ultra flat is ⁓ 55 ± 3%. It is worth reporting that just minor microstructural differences calculated from XRD measurements were observed between samples deposited on the two types of SiOx substrates, as shown in Table 1. The minor decrease of the overall stacking faults density indicated slightly better ordered crystal structure which again corresponds to more compact structure.

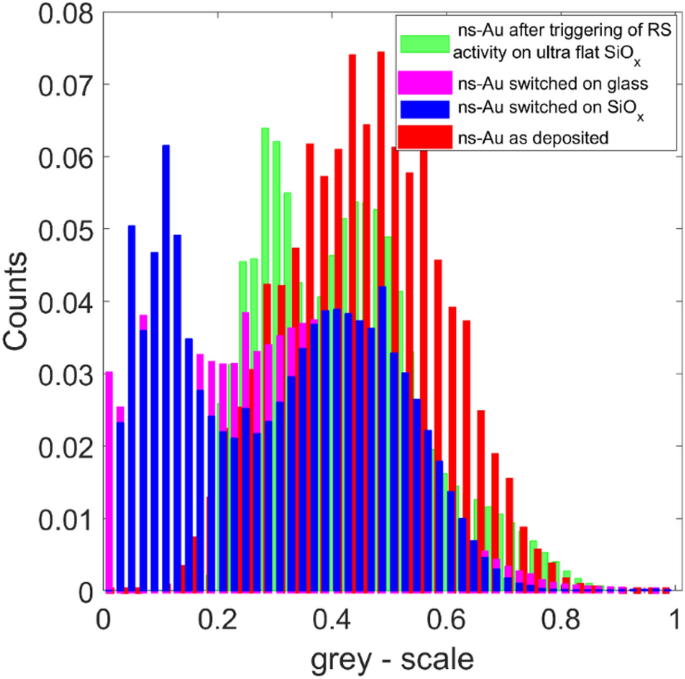

The distribution of surface heights in greyscale of the four SEM images (Fig. 5) confirms the layered morphology of ns-Au/SiOx samples at the nanoscale, while more broaden distributions characterize the as-deposited and the ns-Au/glass morphology at this scale.

Grey-scale distributions of the SEM images shown in Fig. 4.

Electrical characterization

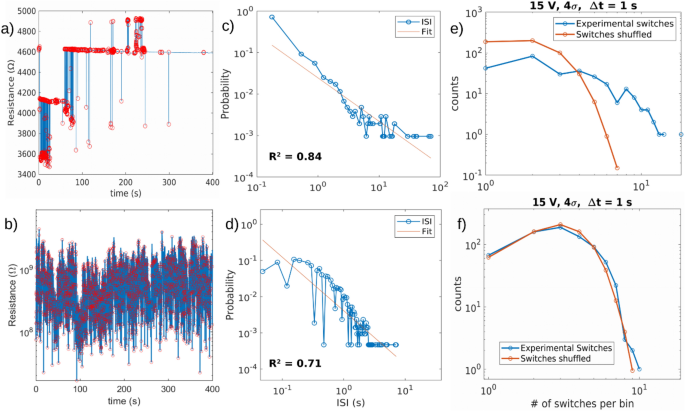

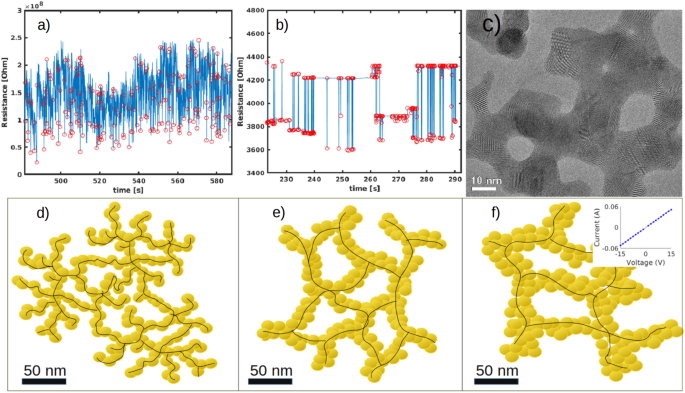

Non-linear electrical properties of resistive switching Au cluster-assembled devices have been characterized, according to the analysis strategy described in the Materials and Method Section, on three film thicknesses (15 nm, 23 nm, 40 nm). Figure 6a,b reports the resistive switching electrical behaviour manifested by the 23 nm thick Au cluster-assembled films deposited on SiOx and glass substrates respectively. The samples characterized by this thickness has been chosen as representative of all the thicknesses explored, since no difference in morphology as also in the time correlation of the electrical response appears related to a change in thickness. The resistive switching activity of ns-Au/SiOx samples (Fig. 6a) is observed only for applied voltages greater than 5 V, whereas for ns-Au/glass, RS is already observed at voltages larger than 1 V, showing lower stability compared to ns-Au/SiOx for comparable resistance values and so lower current density (this aspect is further investigated in the next paragraph). Furthermore, the activation of resistive switching leads the samples to different resistance values, Rns-Au/SiOx ~ kΩ and Rns-Au/Glass ~ kΩ-GΩ. Moreover, the amplitude of the switching events can be as high as the 100% of the resistance value on glass while on SiOx substrates the switching events are rarely greater than the 10% of the resistance. We have further investigated the discrepancy in the temporal distribution of the switching events in the analysed time window. RS events, marked by red circles in Fig. 6a,b, are grouped for the ns-Au/SiOx samples in burst periods followed by silence periods (no switching activity) of different lengths. On the contrary, the RS events observed for ns-Au/glass samples seem not to be grouped in burst periods but are more uniformly distributed on the time sequence.

RS activity over a 400 s time window at constant voltages of 15 V for a 23 nm thick ns-Au/SiOx (a) and ns-Au/glass (b) samples. The switching event (red circle) is identified within the entire set of resistance data (blue data) when two consecutive resistance values differ each other more than 4 times the relative standard deviation of the resistance values computed in a low-noise interval. (c,d) ISI distributions (blue) in log–log scale fitted with power law line shape (orange) calculated from RS activity on the two samples type, respectively. (e,f) Distributions of the number of switching events per 1 s intervals of shuffled and unshuffled data series for ns-Au/SiOx and ns-Au/glass samples, respectively.

In order to quantify the differences of the RS activity time distribution and to evaluate the time correlations of the switching activity, the Inter Switching Interval (ISI)24,33 analysis has been performed following the protocol reported in Materials and Methods section. ISI distributions for ns-Au/SiOx and ns-Au/glass samples are respectively shown in Fig. 6c,d in logarithmic scale from which the mentioned differences are quantitatively evaluated. The RS events grouped in small time windows contribute to the left side of the distribution, while the right side of the distributions considers the events separated by longer time periods; the ns-Au/SiOx samples have a distribution tail much more extended than ns-Au/glass. To quantify the time correlation degree systematically, six different ISI distributions were computed for six different voltage values (± 5 V, ± 15 V, ± 25 V) for each sample. Then the obtained distributions were fitted both with exponential and power law line shapes. The power law distribution manifests a heavy tail which indicates the presence of time correlations, on the contrary the exponential distribution represents independent uncorrelated events47. Thus, comparing the R2 coefficients obtained by the two fitting procedures it was possible to observe a higher correlation degree with power law for ns-Au/SiOx samples than for ns-Au/glass. No significant differences within each of the two systems emerge from the electrical behaviour at different constant voltages, for both the polarities, as well as for different thicknesses. Quantitatively, the subtraction of the power law and exponential R2 fitting coefficients is systematically greater for ns-Au/SiOx samples compared to ns-Au/glass ones indicating a better agreement to a power law distribution for the former system, as reported in Table 2.

We also performed a further analysis following Karsai et al. method35, also reported in Materials and Methods section. The distribution of the number of switching events belonging to intervals of 1 s are reported in Fig. 6e,f for the two different substrates, both for shuffled and unshuffled time series. For unshuffled time series, the switching events are uniformly arranged thus the resulting number of events per time interval distribution does not show the tail expected for grouped events as for the case of unshuffled ns-Au/SiOx samples data series which indicates the presence of correlations. On the contrary, for ns-Au/glass samples the distributions of the unshuffled data do not show a significant departure from the shuffled series. To quantify the difference between shuffled and unshuffled distributions the discrepancy was defined as the difference of the normalized distributions, which is also reported in Table 2. The discrepancies computed for all the analysed data series for each sample strengthen the evidence of a higher degree of time correlations for ns-Au/SiOx samples and a lower correlation for ns-Au/glass samples. We argue that the correlation degree discrepancy is due to the morphological and structural differences of the Au cluster-assembled films due to the forming process previously reported and further discussed in the following.

In situ thermal characterization of the RS forming process

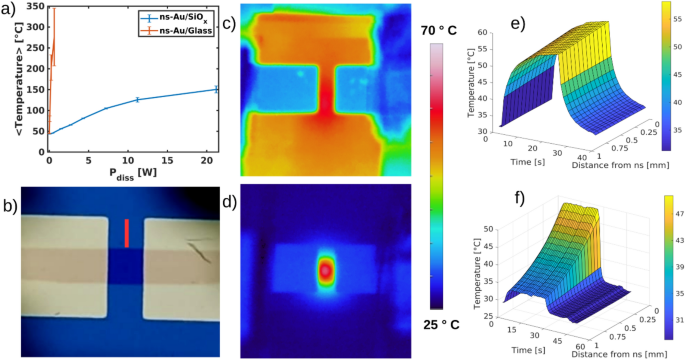

We characterized the evolution of the temperature of the nanostructured films during the resistive switching forming process with a thermo-camera to gain a deeper insight in the mechanisms responsible for the network reorganization. The main electrical and thermal features characterizing the switching triggering of the ns-Au deposited on glass and on SiOx, obtained by electrical measurements at constant voltage and by the IR-video acquired by the thermocamera, are reported in Table 3.

The thermo-camera measurements show that SiOx substrates better dissipate the heat than glass, as it was expected. This is clearly demonstrated by the temperature measurements of the nanostructured film area as a function of the dissipated electrical power, computed as P = I · V, where I and V are the applied current and voltage during the switching procedure, respectively, showing that much higher temperatures are reached on the glass substrates even at lower dissipated power (Fig. 7a). Moreover, due to the different thermal diffusion coefficients, the heat dissipated is much more localized close to the nanostructured thin film when considering glass substrates, (see Fig. 7c,d for comparison). Heat localization was quantified by computing the spatial derivatives in a region perpendicular and next to the nanostructured film, as schematically reported in Fig. 7b. Spatial derivatives were evaluated from the graph showed in Fig. 6e,f in which the substrate temperature is showed as a function of time and distance from the nanostructured films. These are proportional to the spatial gradients and in the case of SiOx (see Fig. 7e) they are almost constant, meanwhile the functional shape of the glass spatial derivatives are power laws, which indicates a much stronger heat localization due to lower heat conductivity of glass. Furthermore, time derivatives of the glass substrates have similar functional shape compared to SiOx but they are 2–4 times higher, pointing out that SiOx substrates need more time to heat up and to cool down due to the higher value of its thermal conductivity. Probably, this extra time could also enable the better ordering of crystal structure, which is observed for the SiOx substrate.

(a) Average temperature reached by the ns-Au film area as a function of the electrical dissipated power for glass and SiOx substrates. (b) Optical image of SiOx substrate equipped with electrodes bridged by the ns-Au film (shaded stripe in the middle), the red bar (1 mm) represents the area from which figure (e) and figure (f) were computed. (c,d) IR-images of the cluster assembled films respectively deposited on SiOx and glass over which the same temperature range is observed at 25 V and 3 V respectively. Heat dissipation is much more localized in the case of glass. (e,f) Temperature of the substrates along the red stripe shown in (b) as a function of the time and distance from the ns-Au film for SiOx and glass, respectively. At time t = 0 s, the power supply is turned on and the sample starts to heat up until the voltage source is turned off and the samples start to cool down. The well localized heat spot is evident in the glass case as like as the faster heating and cooling resulting from different thermal conductivity of the substrates.

The differences of the substrates thermal properties cause the discrepancies observed in the RS forming process suggesting that the onset of the RS activity is due to different relative magnitudes of the thermal phenomena involved. In the glass case the onset of the RS activity was obtained in relatively small times, as reported in Table 3, compared to SiOx. Moreover, the temperatures reached on glass substrates were much higher and localized compared to SiOx and the current densities were at least one order of magnitude lower than for SiOx. Glass provides the nanostructured film much higher temperatures in less time, modifying the structural properties of the cluster-assembled film mostly as a fast-annealing effect on more localized regions. On the other hand, SiOx dissipates better heat and so higher currents and longer times are needed to trigger the RS activity. In this case, electromigration is probably more relevant, compared to thermic effects due to the lower temperatures reached.

Discussion on structural and electrical interplay

In order to understand the effect of the resistive switching forming process on the different electrical properties of ns-Au/glass and ns-Au/SiOx, reported in Fig. 8a,b, we investigated the corresponding morphological and structural organization of the two networks. It is worth to remember that the resistive switching in Au cluster-assembled films is a consequence of the grain boundaries reorganization due to current-induced local Joule heating, which modifies continuously the nanostructure of the system, as demonstrated in previous works26,27,28,29.

(a,b) Constant voltage characterization (15 V) of Au cluster-assembled films deposited on glass and SiOx substrates, respectively. The former shows more uniformly distributed RS events, the latter shows multiple metastable resistance levels and burst activity. (c) HRTEM image of a typical region of the as-deposited cluster-assembled Au film on Si3N4 TEM grid. Each white dot is a single atomic column, and parallel dots lines are the lattice planes. The zones where several parallel dots lines, i.e., lattice planes, are observed correspond to crystal domains. The current flow changes grain boundaries orientation giving rise to RS events. (d) Schematic representation of ns-Au network evinced by SEM images reported in Fig. 4b: yellow dots represent crystal grains; black lines represent possible current paths. Ns-Au network on glass substrate manifests high density of branchpoints, endpoints and a single hierarchical level defined by the nanoscale features characterized by the typical electrical behaviour (a). (e) ns-Au network on SiOx substrate is better connected than on glass and manifests two hierarchical levels defined by nanoscale grains and mesoscale reorganization, responsible of the electrical behaviour (b). (f) Ns-Au network on defect-free surface SiOx substrate present even thicker features preserving ohmic conduction channels. The inset reports the I-V curve of ohmic ns-Au on this flat and low surface defects SiOx substrate.

Figure 8c reports a HRTEM image of ns-Au in which grain boundaries are visible. The modification of the grain boundaries changes the local resistivity of the film and consequently the current redistributes in the neighbour junctions of the metal film26,28,41, in a non-trivial recurrent manner. In fact, the redistribution of the current occurs not only as a function of the nanoscale features of clusters, but it also depends on the morphology of the network at the mesoscale, which influences the spatial propagation of the current, redistributed through the ns-Au thin film, and thus the global film resistance dynamic26. We took into consideration the mesoscale reorganization of the clusters network to explain the different electrical behaviours reported in section “Electrical characterization”, because there were no notable differences in the nanoscale characteristics of the two types of samples, such as grain dimensions and nanoscale defects that emerged from the XRD measurements.

Ns-Au films deposited on SiOx substrates are better connected than on glass, since they manifest bigger connections among islands at the mesoscale. On the other hand, despite the coverage of the two samples is approximately the same, ns-Au/glass samples show more holes, more branchpoints and more ending points, stressing a more fragile and intricated structure composed by thinner and more tangled connections, compared to ns-Au/SiOx samples. Thus, the Joule heating effect due to a further application of constant voltage could be more detrimental for the small connections of Au clusters on glass, leading to severe junction rupture and continuous current redistribution to the neighbours in several pathways, which determines the great continuous resistance changes observed (up to 100% of the film resistance value, Figs. 6b and 8a). Conversely on ns-Au/SiOx samples the lower number of branchpoints and the slightly larger size of the paths promote a correlated current redistribution and probably allow the perturbation propagation toward more distant regions, enhancing the mutual interaction of distinct parts of the system, resulting in the observed correlated resistance changes (up to 10% of the film resistance value, Figs. 6a and 8b).

Moreover, we observed more frequent resistance changes for ns-Au/glass samples compared to ns-Au/SiOx and this could be again a consequence of the less compact and badly connected network at the mesoscale for the former system, schematically shown in Fig. 8d. In fact, smaller morphological features, characterized previously by SEM analysis and shown in Fig. 5, require less current and less time to be modified resulting in a continuous current redistribution due to grain boundary modification resulting in frequent resistance changes. On the contrary, Au clusters films connections on SiOx substrate, schematically reported in Fig. 8e, are more compact and well-organized thus much more current and time are needed to significantly modify the mesoscale junctions leading to longer periods of time in which no resistance changes above the noise level.

The close interplay between structural and electrical properties of cluster-assembled gold films is further confirmed by the study of a ns-Au sample deposited on flat and less defective SiOx substrates. This ns-Au/SiOx ultra flat sample manifested ohmic electrical behaviour even after the procedure to trigger the RS activity because the mesoscale connections are even bigger than in the SiOx case so preserving ohmic conduction channels.

In ns-Au/SiOx samples the nanoscale structure made of grain of 10 nm size and a mesoscale morphology characterized by islands and larger mutual connections than those of the ns-Au/glass samples, define a structural hierarchy which translates in a temporal hierarchy the resistive switching events; namely the time required to modify the nanoscale structural features could be lower compared to the time required to modify the mesoscale structural features, thus justifying the observed power-law distribution of the electrical time series25. Conversely, cluster networks on glass manifest less defined hierarchical levels separation, due to the smaller size of the mesoscale features (~ 10 nm), thus resulting in uniformly distributed RS events, namely in uncorrelated electrical activity. Moreover, the ns-Au network on ultra-flat SiOx, Figs. 4d and 8f, present even thicker morphological features compared to ns-Au/SiOx network, Figs. 4c and 8e, thus not showing resistance variations and preserving ohmic conduction channel. Interestingly, in literature48 there are reported other examples of networks which by presenting more hierarchical levels manifest complex critical behaviour thus being characterized by power laws distributions in their dynamics as like the ones we observed in the temporal distributions of the RS activity. The hierarchical levels of the cluster-assembled film deposited on SiOx organized into greater complexity promotes the critical48 and therefore the more correlated behaviour47 of the system, compared to the ns-Au/glass sample. This evidence stresses not only that the ns-Au/SiOx devices RS activity exhibits similar statistical properties as the one observed in biological neuronal networks16,17,18,49, but more interestingly that this activity is related to the ns-Au/SiOx network connectivity which is higher than in the case of ns-Au/glass network. The latter is more disordered and with less hierarchical levels separation, morphology that brings it far from the mammalian brain network which manifests in a hierarchical topology50,51.

[ad_2]

Source link