[ad_1]

“My old Dell XPS 15 has gotten sluggish. The battery dies easily. It’s heavy to cart around, anyhow. Now that I’m going out in public again, I need a new work machine.”

These were the thoughts circling my head at yesterday’s Framework event — where the company known for its easily-upgradable laptops announced new chips and a new, longer-lasting battery. “Battery life has consistently been the main negative for the Framework laptop,” said CEO Nirav Patel, hitting on the one reason I’d only ever admired the company’s laptops from a distance. This morning, without that one reason to hold back, it was time to put down a $100 deposit for my own Framework Laptop 13.

But I didn’t — because Framework wouldn’t sell me that battery unless I bought more components than I needed.

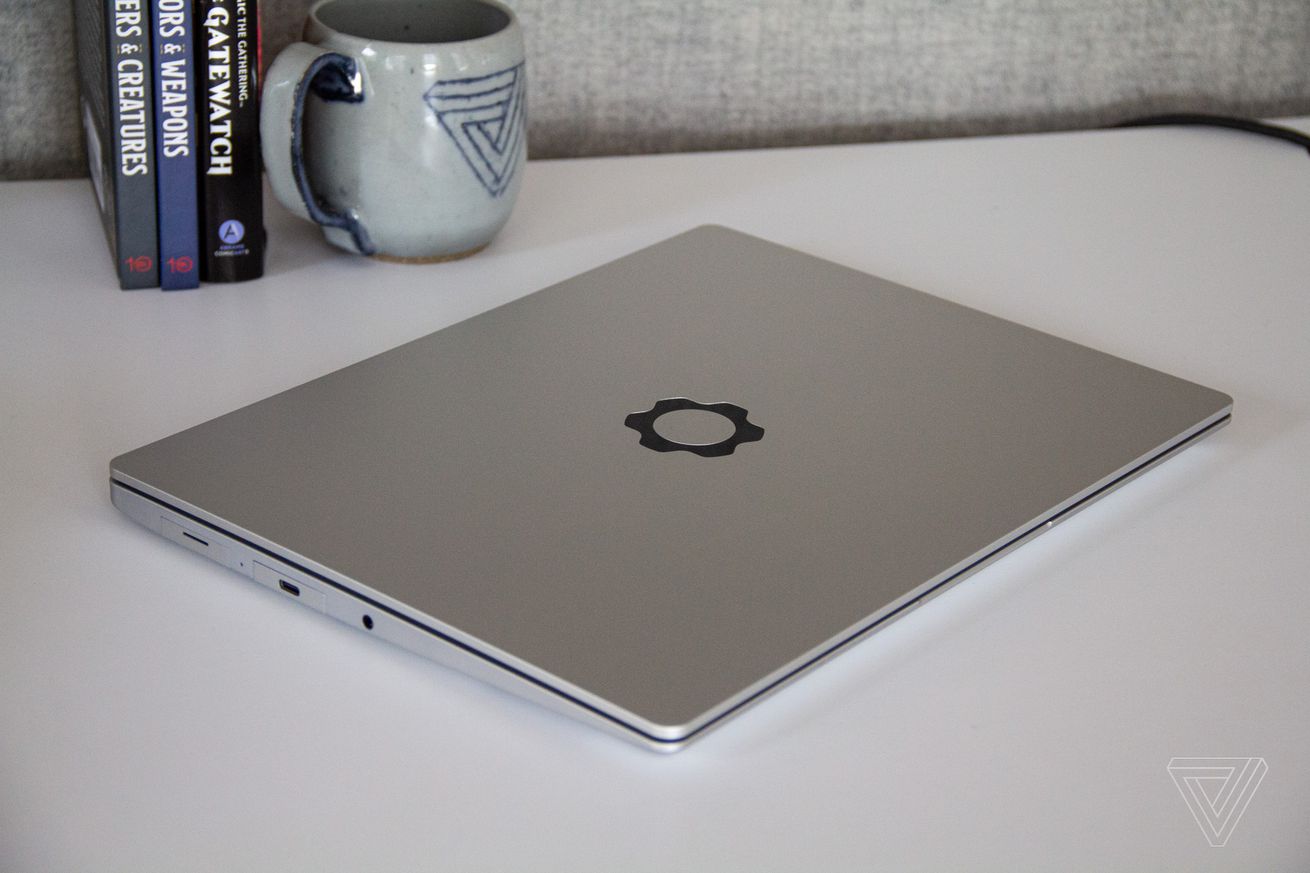

/cdn.vox-cdn.com/uploads/chorus_asset/file/24535211/framework_configurator.jpg)

Screenshot by Sean Hollister / The Verge

See, while the Framework Laptop 13 starts at $1,049, or $849 for a barebones kit, that model only comes with the old 55Wh battery alongside a Core i5 or Ryzen 5 chip. To get the 61Wh battery inside, Framework makes you spend at least $320 more for a Core i7 or Ryzen 7 instead. Or, I could additionally buy a 61Wh battery to swap into the machine for $69 and have the 55Wh battery sitting around turning into e-waste.

I couldn’t understand it. This is the company that prides itself on modularity, the one that told me yesterday how it’s trying so hard to reduce e-waste that it’s experimenting with external cases for various components so they’re not just sitting around. They’ve clearly got these batteries sitting on the shelf to order separately — why can’t I just pay the difference?

So I emailed Framework’s CEO. I wasn’t expecting him to reply. But he did, and I never would have guessed there were so many different logistical reasons behind the decision.

Here’s the first part of his reply:

Hi Sean, we kept the 55Wh in the Base configurations for 1[3]th Gen and for Ryzen 7040 Series in order to keep the price low. Despite massive inflation over the last year and increases in costs for just about all materials and components aside from memory and storage over the last year, we were able to hold the pre-built base price to the same as 12th Gen, $1049.

This is both because the 61Wh battery is more expensive, and because our cell supplier has a substantial amount of material prepared for 55Wh. We could either pay to purchase and scrap that material, which would be totally against our mission, or find a productive outlet for it, which we did through the Base SKU.

For offering it as a configuration option, each new variable in the configuration that is part of the core laptop assembly multiplies the amount of inventory and supply chain complexity we need to manage (CPU options * keyboard languages [on pre-built] * DIY vs pre-built * any new configurable option = number of SKUs). Since we are a small team, we focus on keeping the assembled SKUs as few as possible, while enabling configuration on items that are not pre-assembled like OS, memory, storage, Bezel, and Input Cover on DIY Edition and Expansion Cards on all configs. We also keep the Marketplace as an “escape valve” for items that aren’t available pre-configured, like alternate speakers, hinges, displays (e.g. glossy now that we default to matte), and battery.

I replied back:

“I understand the 55Wh inventory problem, and the incentives around core laptop assembly SKUs, but I can’t wrap my head around the DIY edition configurator. If you are putting together a box full of parts for me to assemble, and you have both batteries on the shelf from which you are pulling the parts (as you do, in your marketplace) why would you tell me I can have one of the parts on the shelf, but not the other?”

Here’s Patel again:

The end user assembly process for the DIY Edition now involves installing memory, storage, Operating System, and now also Bezel and Input Cover. The laptops themselves are assembled in high volume in a serial production line at our factory, while the items selected in the DIY Edition are added to the package per-order at the fulfillment warehouse.

We define the factory-assembled vs user-installed items based on a combination of ease of assembly (the reason the WiFi card is now pre-installed and a factor for battery, hinges, Mainboard, speakers and display being pre-installed), impacts on packaging size (the most compact is actually pre-assembling everything like on pre-built configs, which also minimizes the carbon footprint of shipping), and also regulatory reasons. For batteries specifically, batteries assembled in equipment are regulated differently than packing them separately. This is part of the reason replacement batteries weren’t available in the Marketplace for a period of time after we launched.

Ultimately, building any product, and especially one as logistically and operationally complex as a DIY Edition laptop, is about balancing hundreds of different tradeoffs to reach a result that delivers a good user experience, minimizes environmental impact, and is also executionally feasible.

As a consumer, this doesn’t quite satisfy me: I’m still not willing to pay $320 extra for a CPU I don’t need, and I’d feel icky paying $69 for the new battery and then having to figure out what to do with the extra battery pack.

But at least I understand the decision. No matter which SKU you buy, the company sticks the battery and almost every other component into the chassis at the factory and does that in a limited number of ways for efficiency’s sake. To give me the machine I want to buy, the 40-person company would have to change how it assembles laptops or swap batteries after the fact — and right now, the incentives apparently aren’t aligned that way.

[ad_2]

Source link