[ad_1]

“Farm profitability is something that I live and breathe every day,” says Shay Foulk, Sparland, Ill., who works as both an ag business consultant and farmer. “When we talk about investing back into the farm, I have to consider my own family’s future plans.”

Years of record farm incomes, rising interest rates and grain market volatility have caused Foulk to wonder — what investments can be made today on the farm that bring value for generations?

Foulk is a farm business decision-making consultant for Ag View Solutions, so he decided to survey their clients on that very question. His big takeaway? Local basis creates the most variability in farm income.

“We’re talking about huge dollars for farmers,” Foulk says. “It was about a $2-per-bushel spread in corn and roughly a $3-per-bushel spread in soybeans.”

Storing grain on the farm is a good way to manage basis, because it gives farmers flexibility to take advantage of price pushes during periods of high demand, rather than selling during harvest when the market is saturated in regions with a negative basis.

Foulk sees this on his own farm in northwestern Illinois, where he raises corn and soybeans.

He has 12 bins on the farm with storage capacity for 80% of his crop. Foulk uses hedge-to-arrive futures contracts to capture carry in the market with the option of later delivery.

“Our storage has paid for itself many times over in the last several decades,” he says, noting that many of his bins were built over 35 years ago. “The time has come for us to invest in some more storage for the future of the farm.”

But grain storage isn’t cheap. Foulk says often, farmers see the upfront cost and shy away from the investment without calculating the long-term payoff or considering government programs that can help offset their costs.

His solution? Foulk developed a Should I Build Storage? calculator. It’s a free spreadsheet tool to aid farmers in storage investment decisions by analyzing costs, production and payback period.

“The tool can help farmers make better decisions and take the emotion out of these choices,” Foulk explains. “Since there’s some excess cash out there right now, I’d expect demand for storage to be stronger than ever this year.”

MARKETING: “Putting corn or beans in a bin just to put them in a bin isn’t a good business plan,” says Eureka, Ill., farmer Chad Leman. “But if you understand marketing, carry and basis, then you can really pay for a bin in a hurry.”

Joe Janzen, University of Illinois agricultural economist, agrees, noting that as the market shifts to a period of lower prices and profitability, grain storage could mean the difference between profit and loss for many.

“Grain markets often provide good returns to storage, but not every year,” Janzen says. “Storing grain pays over the long haul, but now farmers may have a constrained ability to build and use storage in a lower-margin, high interest-rate environment. The upfront costs are what they are. They’re never cheap enough, and you always wish they were lower.”

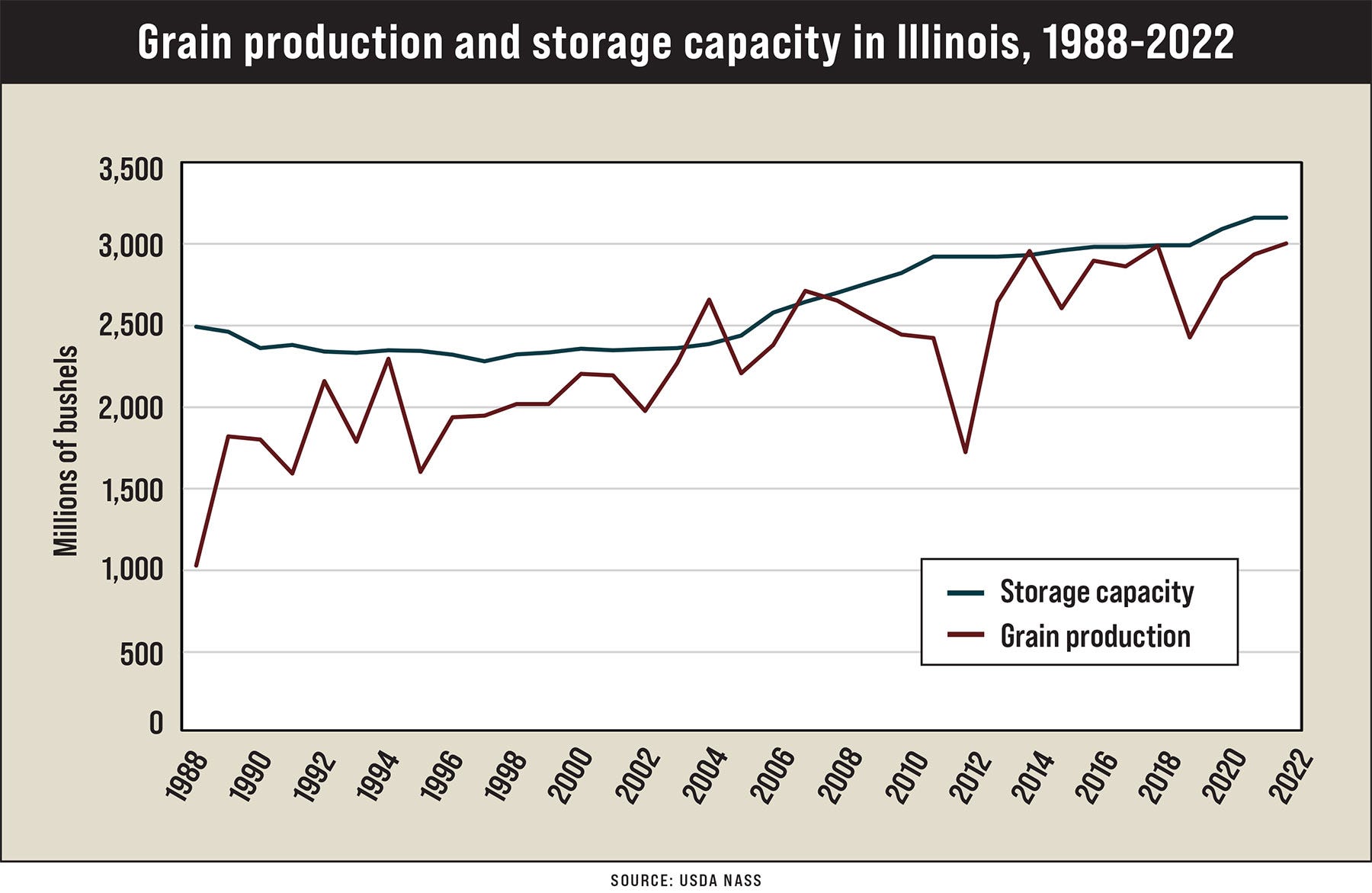

Janzen has seen a steady increase in on-farm grain storage in the last several decades as production has increased.

“Between 2005 and 2022, both grain production and storage capacity in Illinois have grown by about 34 million bushels per year,” he says.

But just because farmers can store grain doesn’t mean they should.

“Making money from storage requires disciplined marketing,” Janzen says. “The danger is that sometimes storage allows you to make bad marketing decisions and hold on to grain for far too long.”

Janzen’s research indicates that the average grain farm in Illinois holds roughly 80% of a year’s production in inventory on Dec. 31, betting on further price appreciation.

“The stakes for post-harvest grain marketing decisions are higher than ever,” says Janzen, explaining that as interest rates increase, so do the cost and risk for storing grain for long periods. “With potentially bigger profits comes a significant downside risk.”

For farmers considering an investment in grain storage, Foulk and Janzen recommend considering:

Cost vs. benefit. Running the numbers using realistic prices, numbers and historical averages is the first step to adding storage. Foulk’s storage calculator is a great way to get started.

USDA programs. The Farm Storage Facility Loan Program offers low-interest financing options to build or upgrade grain storage. The program offers a $500,000 maximum loan for storage, drying and handling equipment on small to medium-size farms.

A marketing plan. Grain storage profits are only as good as a farmer’s marketing plan. Foulk recommends Joe Vaclavik with Standard Grain or Jarod Creed with JC Marketing and Ag Financial Services to aid in marketing decisions. Janzen recommends the grain marketing plan templates published by the Center for Farm Financial Management at the University of Minnesota to help make decisions.

Benefits beyond the bin. Grain storage offers control over trucking logistics, harvest timing and farm labor. Storage also adds value to the farm as the next generation returns or the current generation seeks retirement.

BASIS: “You have to pay attention when keeping grain,” says Bill H. Voorhees of Maroa, Ill. “There’s so much money involved, and it’s a lot to take care of. It’s easier to take grain to the elevator and let them worry about it. But we’ve lived off the basis we’ve captured from this system for years.”

To put these recommendations into practice, Prairie Farmer visited three Illinois farmers for their advice on grain storage and handling systems.

Building gradually

Maroa, Ill., farmers Bill H. and Bill R. Voorhees have been adding onto their bin site since 1987. The father-son duo has added or updated a portion of the system every two or three years, doing the concrete work and assembly themselves. They began with 150,000 bushels in 1987, and today they have 700,000 bushels of grain storage, including a 5,000-bushel-per-hour dry leg, 10,000-bushel-per-hour wet leg, 10,000-bushel-per-hour unload leg, Sukup Mixed-Flow Dryer and nine bins surrounding the site.

One of their main goals was to improve grain quality by switching from augers to conveyors. The Voorheeses say the key to expanding over three decades is thorough planning.

“Every farm is different, but you have to plan ahead for future building,” Bill R. says. “We’ve told our friends to build their grain systems in a straight line because we’re cramped here when we load trucks. But to go further would mean to build higher, and with the winds out here, that’s an accident waiting to happen.”

GRADUAL: Bill H. (left) and Bill R. Voorhees have been adding onto their bin site over the last several decades, doing much of the assembly and concrete work themselves.

Bill R.’s favorite piece of their current setup is their grain dryer.

“We used to have a tower grain dryer and upgraded to a Sukup Mixed-Flow Dryer because of its efficiency, capacity and grain quality,” he explains. “We’ve been really happy with it.”

This year, they added an Amber Agriculture CO2 sensor in their 180,000-bushel bin to monitor carbon dioxide levels, ensuring grain maintains safe temperature and humidity levels.

“You have to pay attention when keeping grain,” Bill H. says. “There’s so much money involved, and it’s a lot to take care of. It’s easier to take grain to the elevator and let them worry about it. But we’ve lived off the basis we’ve captured from this system for years.”

Building with livestock in mind

Eureka, Ill., farmer Chad Leman expanded his grain storage setup in 2016 to take advantage of marketing opportunities and to store feed for his 110,000 pigs marketed annually. His bin site has six dry bins and two wet bins with a capacity for 500,000 bushels of corn and 50,000 bushels of seed beans, plus five grain legs, two grain dryers and a feed mill. Leman stores, dries and mills all of his corn for pig feed.

If he were to start the project over, Leman would have scaled everything up.

“Build it bigger than think you’ll need, because infrastructure like electricity, driveways and all-weather access is the same no matter the size,” Leman says. “You’ll need dump pits, power and loading capacity regardless of how big it is. The cost of building bins gets cheaper as the capacity goes up, so I would encourage building as big of bin as you can.”

LIVESTOCK: Chad Leman expanded his grain storage setup in 2016 to take advantage of marketing opportunities and store feed for his 110,000 pigs marketed annually.

All of Leman’s bins and unloading lanes have been planned with expansion and efficiency in mind.

“Plan for where your next bin’s going to go,” Leman says. “We created a new lane of traffic to go around our 250,000-bushel bin to avoid bottlenecks with dumping wet corn and mixing feed; plus, this setup allowed for future expansion. Wet bins are really expensive, so it’s tempting to cut corners on wet bin capacity, but that would really shortchange any future growth.”

Leman says understanding grain marketing is the key to returns on grain storage.

“Putting corn or beans in a bin just to put them in a bin isn’t a good business plan,” he explains. “But if you understand marketing, carry and basis, then you can really pay for a bin in a hurry.”

Building for the future

Roy Wendte, Altamont, Ill., first overhauled his grain system in 2000, adding onto the existing bin site that his parents started in the 1950s. In 2022, the Wendtes determined they’d outgrown their existing storage and made another upgrade.

Today, Wendte Farms has 580,000 bushels of corn storage and 180,000 bushels of soybean storage, plus wet legs, a dry leg, a tower dryer, pit and scale. Wendte also has an Apex Building, or canvas-framed storage shed, on the farm that can store up to 300,000 bushels of corn. Today, half of the building is used for corn storage and the other half stores chicken litter for fertilizer.

“We’re working with more grain than ever before,” says Wendte, comparing today’s 250-bushel corn to yields from 10 or 20 years ago. “There’s a need for speed, as we can shell as fast as we want. The dryer never shuts off.”

He says the setup makes his farm more efficient, plus allows him to take advantage of marketing opportunities.

“Why let the elevator collect the basis?” Wendte says. “You might as well be the one getting paid for storing your grain.”

EXPANSION: Roy Wendte added onto his family’s grain storage in 2000, and then overhauled his system again in 2022 to meet the needs of higher production and expansion as his children joined the farm.

Wendte and his brothers designed their current system to allow for future expansion opportunities and yield increases. Wendte has grown the farm to make room for his three children plus their spouses and children. He anticipates their current grain handling and storage setup will be on the farm for decades.

“Grain storage has given us more time as a family as the farm has expanded,” he explains. “Everyone’s goal is to operate on a faster and larger scale, but we also want time for things off the farm. There’s value in being able to manage how soon you get in the field, when to haul grain and where to get the best price.”

Wendte says he’s pleased with their current setup, and says his best advice is not to skimp on space.

“Don’t cut corners. You’ll undoubtedly regret it down the road,” Wendte says.

[ad_2]

Source link